Installation and Setup of Grease Hose Reels

Installing and setting up Euroreels grease hose reel is a relatively straightforward process. Here are the general steps to follow:

- Determine the Mounting Location: Choose a suitable mounting location for the grease hose reel. Consider the accessibility of the reel, the proximity to the equipment that needs lubrication, and any space constraints in your facility. Ensure that the mounting location provides a stable and secure base for the reel.

- Prepare the Mounting Surface: Prepare the mounting surface by cleaning it and ensuring that it is free from any debris or obstructions. If necessary, use appropriate hardware or brackets to secure the reel to the mounting surface.

- Attach the Reel: Attach the grease hose reel to the mounting surface using the provided mounting brackets or hardware. Follow the manufacturer’s instructions for proper installation.

- Connect the Hose: Connect the grease hose to the reel using the provided fittings or connectors. Ensure that the hose is securely attached to the reel to prevent any leaks or disconnections during use.

- Connect the Other End: Connect the other end of the hose to the equipment or machinery that requires lubrication. Use the appropriate fittings or connectors to ensure a secure and leak-free connection.

- Test the Reel: Once the installation is complete, test the grease hose reel to ensure that it is functioning properly. Check for any leaks, kinks, or obstructions in the hose. Test the retraction mechanism to ensure smooth and effortless hose retraction.

- Adjust and Fine-Tune: Fine-tune the reel as needed to ensure optimal performance. Adjust the tension of the retraction mechanism, if applicable, to achieve the desired hose retraction speed. Make any necessary adjustments to the hose length or positioning to ensure easy access to all parts of your equipment.

The installation of grease hose reels can be daunting task, by following these steps, you can easily install and set up Euroreels grease hose reel in your facility, allowing for effortless maintenance and lubrication of your equipment.

For more detailed information, please feel free to contact us

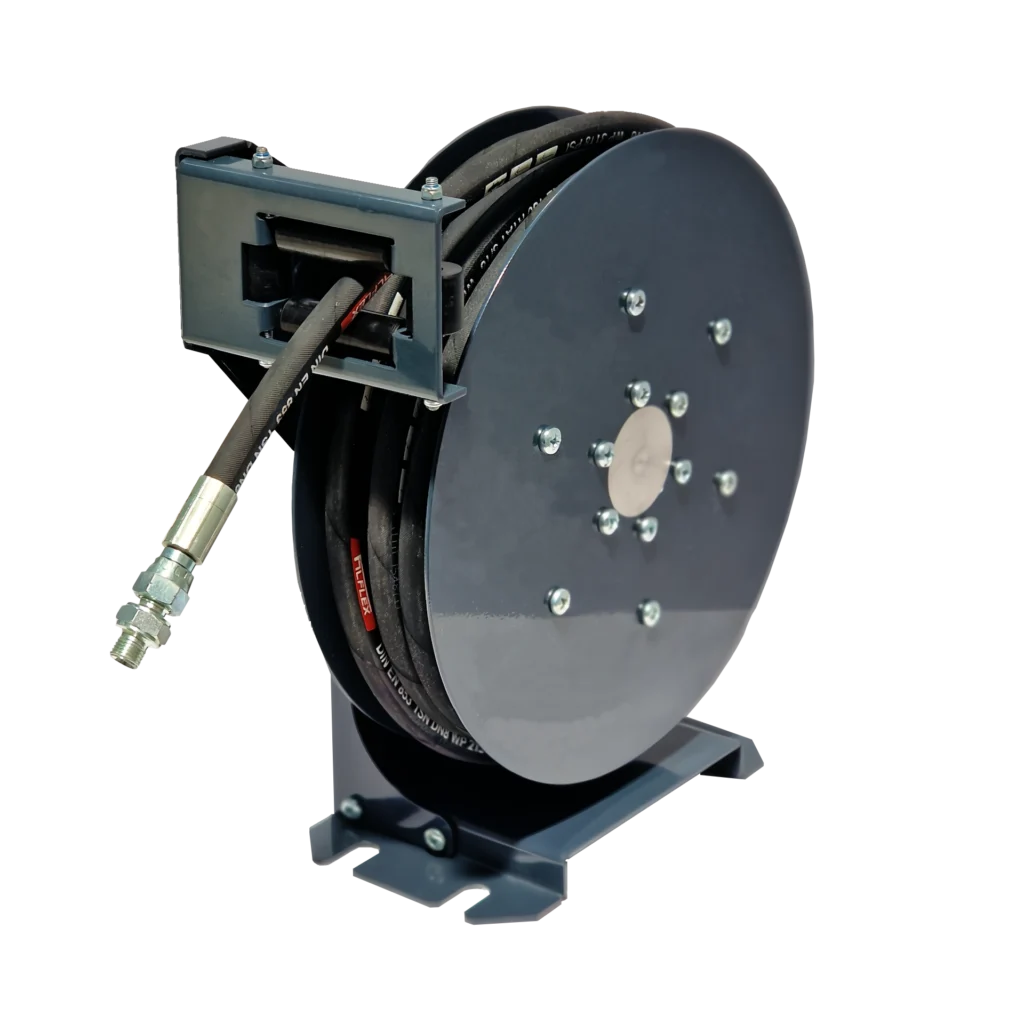

Types of Grease Hose Reels

Euroreels grease hose reels come in various types and configurations, each designed to meet specific needs and preferences. Here are the most common types of grease hose reels:

- Manual Hand-Cranked Reels: Manual hand-cranked grease hose reels are the most basic type of reel. They feature a manual crank that is used to retract the hose. These reels are typically more affordable and are suitable for applications where mobility is not a concern. Manual hand-cranked reels are often used in smaller workshops or facilities where the equipment is stationary or requires minimal movement.

- Spring-Driven Reels: Spring-driven grease hose reels are equipped with a spring mechanism that automatically retracts the hose after use. These reels are popular for their convenience and ease of use. With a spring-driven reel, the hose is automatically wound back into the reel with a simple tug, eliminating the need for manual winding. Spring-driven reels are suitable for applications where frequent movement is required, such as mobile equipment or workstations that require flexibility.

- Motor-Driven Reels: Motor-driven grease hose reels are the most advanced and versatile type of reel. These reels are powered by an electric or hydraulic motor, which provides automatic and effortless hose retraction. Motor-driven reels are ideal for heavy-duty applications or operations that require frequent movement and flexibility. With a motor-driven reel, the hose can be retracted at the touch of a button, saving time and effort.

- Open and Enclosed Reels: Grease hose reels can be further categorized into open and enclosed reels based on their design. Open reels feature an exposed drum, allowing for easy access and maintenance. Enclosed reels, on the other hand, have a protective casing that covers the drum, providing additional protection against contaminants and reducing the risk of damage. The choice between open and enclosed reels depends on the specific requirements of your application and the level of protection needed.

Not the reel you are looking for? Check our products for more options!