What is an Oxygen Acetylene Hose Reel?

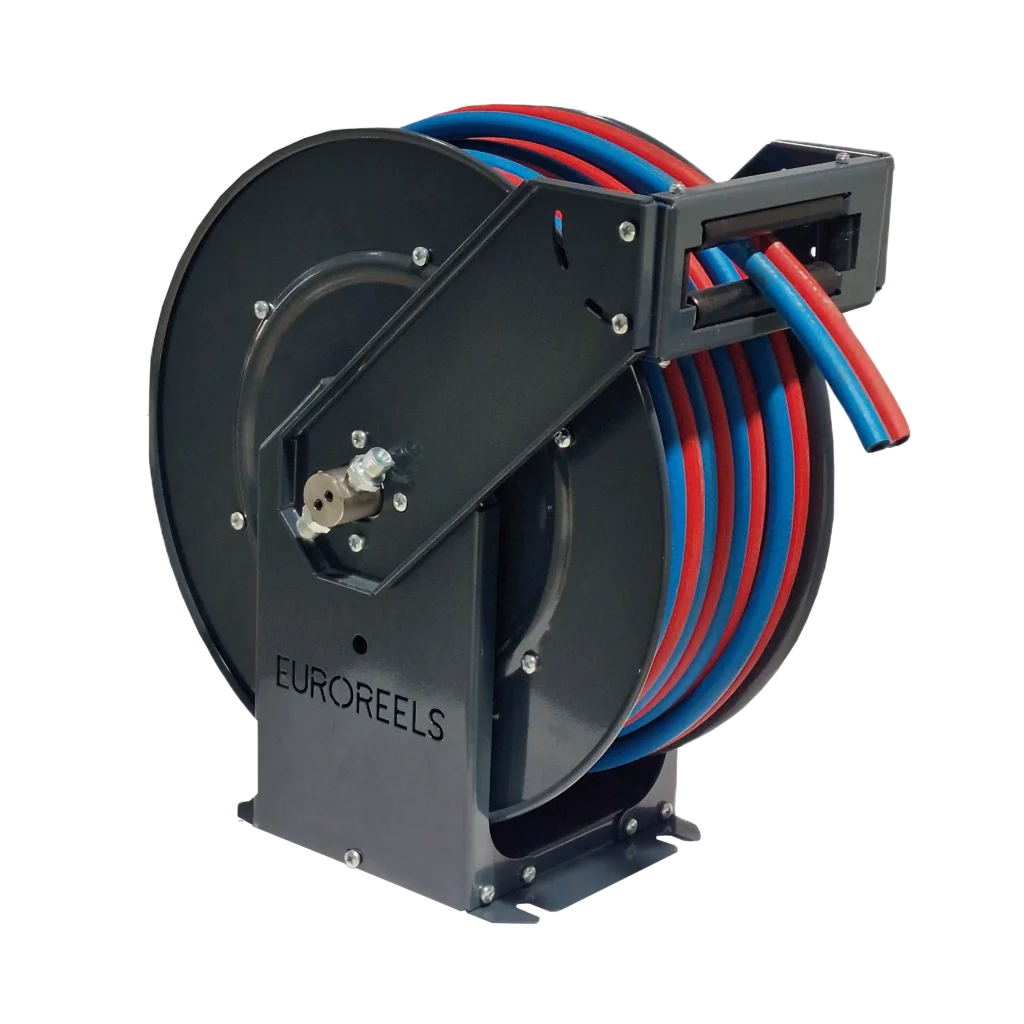

An oxygen acetylene hose reel is an industrial device designed to keep hoses organized and facilitate the transport of oxygen and acetylene gases, commonly used in welding and cutting operations. Known in the market as oxygen acetylene reels, these hose reels enhance mobility and ease of use on job sites, ensuring workers can perform safely and efficiently. Our Euroreels reels are typically robust and durable.

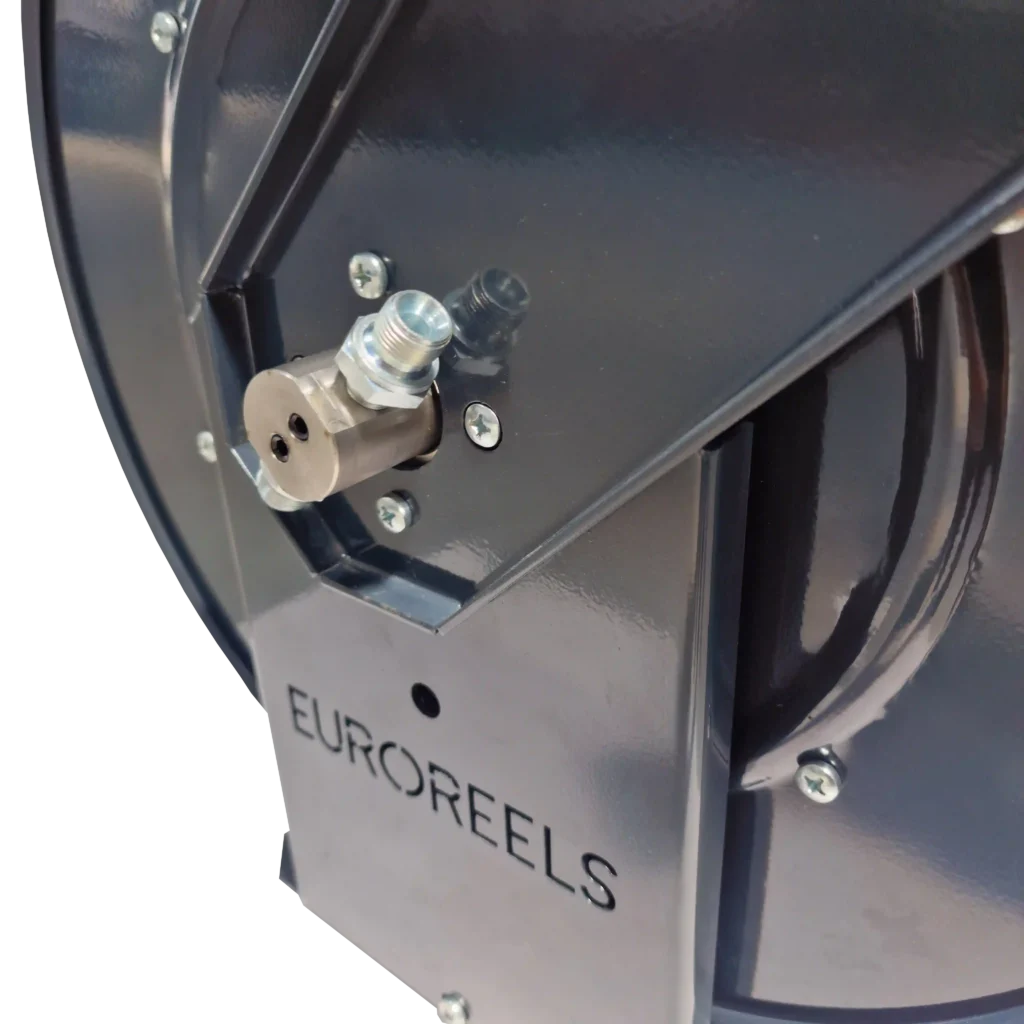

Oxygen acetylene hose reels are built with two separate swivels and a single shaft, enabling the transfer of gases like oxygen, acetylene, and LPG without mixing. In addition to dual-hose reels, we also offer reels specifically for oxygen or acetylene hoses.

Operating Principle

The operating principle of hose reels also applies to oxygen acetylene hose reels. The industrial reel holds the oxygen acetylene hose, which can move thanks to a specially designed swivel. The supply hose is mounted on a fixed shaft, allowing the reel hose to move while the supply hose remains stationary. This prevents the hose from kinking or twisting, ensuring longer hose life and reliable operation.

Oxygen and acetylene are frequently used in industrial applications such as metal cutting and welding. These gases are transported and handled using specialized equipment. The oxygen acetylene hose reel ensures the safe transport of gases to welding or cutting machines. The reel typically holds oxygen and acetylene hoses, allowing the user to move freely within the workspace.

Latching Mechanism of Welding Hose Reel

The latching mechanism, designed to prevent strain on the operator, features a pawl and ratchet system that keeps the hose fixed at the desired length. It automatically rewinds the hose when pulled slightly and released.

![]()

Euroreels Oxygen acetylene hose reels, while primarily designed for twin hoses used in welding and cutting, can also be configured for single hoses as separate oxygen or acetylene hose reels.

Applications for Oxygen Acetylene Hose Reels

- Metal Cutting and Welding

- Construction and Ironwork

- Repair and Maintenance

- Automotive Industry

- Industrial Maintenance

- Shipbuilding and Shipyards

Technical Specifications of Oxygen Acetylene Hose Reels

| Description | Features |

|---|---|

| Length | 50 meters (Spring-loaded) |

| Working Pressure (bar) | Up to 25 bar |

| Working Temperature (°C) | -5°C to +60°C |

| Frame Material | S235JR (ST-37) (Standard) / SS304-SS316 (Optional) |

| Shaft Material | SS303 (Standard) / SS304-SS316 (Optional) |

| Swivel Material | CuzN37 (Brass) |

| Flow Path Feature | Completely stainless |

| Automatic Sequential Winding Feature (*) | Optional after 20 meters |

| Hose Direction | Adjustable Bottom – Top (Varies by model) |

| Color Options | RAL5015 (Standard) – Optional Color Available |

Why To Use Oxygen Acetylene Hose Reels?

- Mobility: Oxygen and acetylene hose reels keep hoses neatly coiled, giving workers greater freedom of movement. This allows for easy maneuvering and more efficient operations on the job site.

- Safety: These hose reels ensure safe storage and protection of gas hoses. Properly coiled hoses prevent tripping and tangling, reducing potential hazards.

- Efficiency: Quick deployment and retraction of hoses allow workers to start and finish tasks faster, thus enhancing workflow efficiency.

- Easy Storage and Transport: Hose reels keep hoses organized for easy storage and transport, maintaining a tidy work environment.

- Versatility: Oxygen acetylene hose reels are used mainly in welding but are also suitable for metal cutting, construction, maintenance, and repair across various industries.

- Durability: High-quality hose reels made from durable materials ensure long-term, reliable service. This provides customers with a dependable solution for their gas hose needs.

Not the reel you are looking for? Check our products for more options